Northwest Steel Fab Inc.

Northwest Steel Fab, Inc. has been fabricating structural steel and applying high performance coatings since 1994.

Capabilities

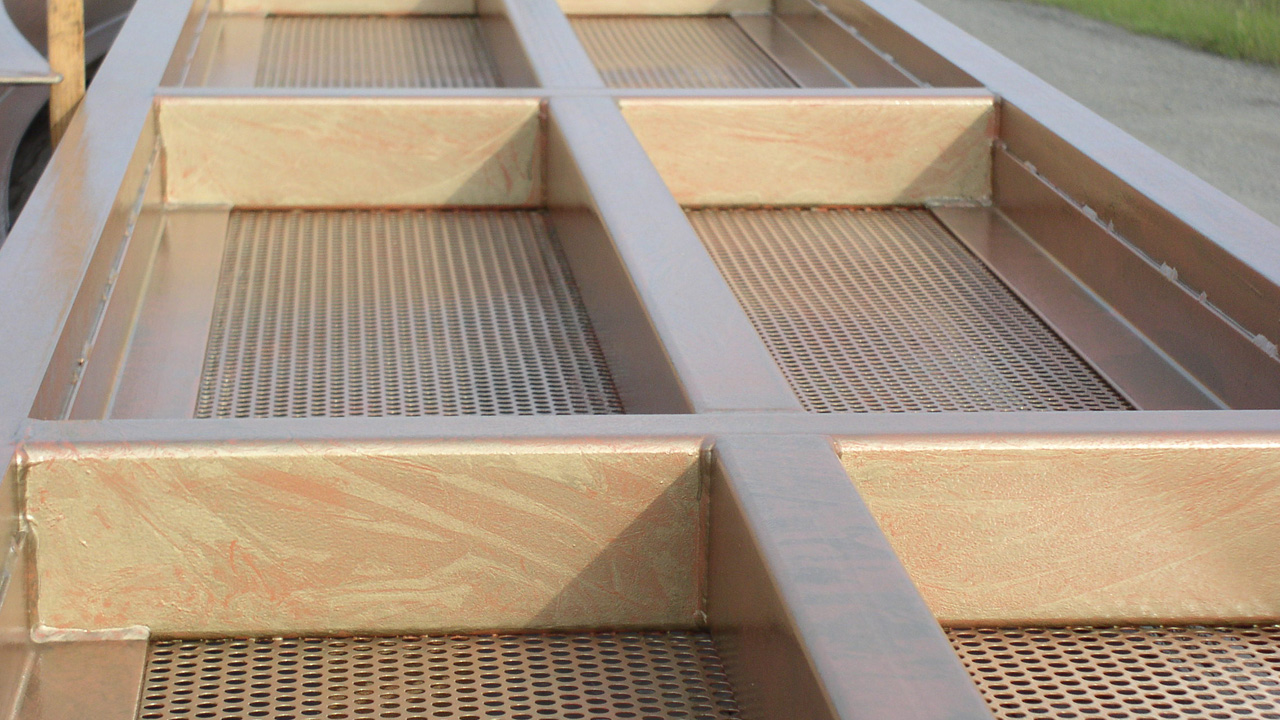

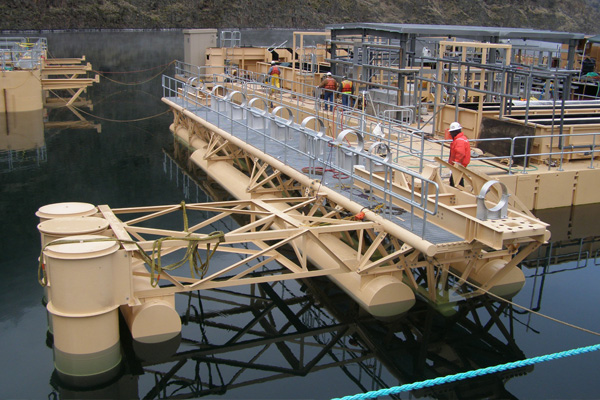

At Northwest Steel Fab Inc., we’re your premier destination for custom metal fabrication and coating solutions. With a track record of precision and excellence, we specialize in crafting innovative products from steel, aluminum, and stainless steel. Our commitment to quality and diverse expertise ensures that your projects receive the attention and care they deserve.

View CapabilitiesIndustries Served

Facility & Equipment

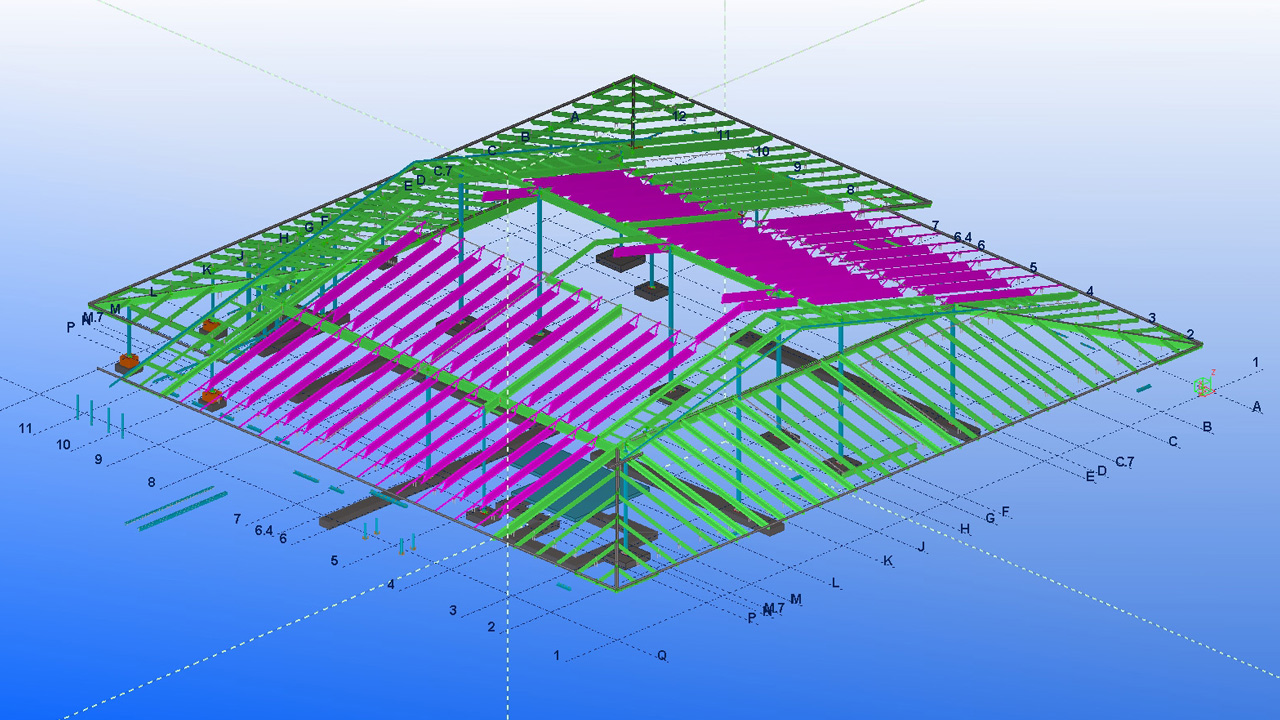

95+ full time employees-Our shop operations run day and night with full crews on both day and swing shifts. “We are working on your steel fabrication projects almost 24 hours a day”. We also offer the most comprehensive services to our customers in the industry, Steel Detailing using TEKLA, Steel fabrication and processing, Grating and Handrail fabrication along with our coatings department consisting of Wheelabrating, Sandblasting and high performance coatings all at one location. We are AISC certified to the Building Standard, Intermediate Bridge with Fracture Critical and Sophisticated Paint endorsements. We are also CWB (Canadian Welding Bureau) Certified to 47.1.

Contact Us20+ acres with 12 acres of lay down area, all fully developed. State of the art fabrication, wheelabrating and sandblasting for paint preparation

No job is too big, no job is too small. High definition plasma processing on multiple machines in multiple bays, certified welding on steel, stainless steel, and aluminum.

AISC Complex Coating Endorsement - Wheelabrator with 60" opening, Sponge-Jet sandblasting, steam cleaning, pressure washing, and temperature controlled paint storage.

AISC certified Advanced Bridge Fabricator, Building Fabricator, Hydraulic Fabricator and Fracture Control Endorsement. Our facility is AWS, WABO and CWB certified. Ready for GMAW, FCAW, SAW, SMAW, and stud welding.

Two Python X-6 axis high definition robotic plasma processing machines, Controlled Automation burn table up to 10' think plate. Angle Master punch and drill machine, DG-1250 - Miter Series band Saw 49"x20", Peddinghaus plate processor, 80 ton Piranha, 50 ton Piranha, Hyd-Mech 20A saw 30" x 20", grating panel saw.

Clark 30,000lbs, Hyster 28,000lbs, (2)Hyster 19,000lbs, (2)Hyster 16,000lbs, Toyota 15,000lbs, (2)Hyster 14,300lbs, Toyota 8,000lbs, (2)Toyota 5,000lbs, (3)Toyota 3,500lbs, Toyota 2,800lbs, Caterpillar 3,000lbs.

5x 10ton overhead cranes, 7.5ton overhead crane, 5ton overhead crane, 14x 1ton work area jib cranes.

4x PC workstations with Tekla Xsteel-3D structural steel modeling and advanced detailing.